This report relates to the development of a new tablet – Htab Zero. Its product development process is compared to the baseline product – HUAWEI MediaPad M5 Pro tablet. The justification for selecting this baseline product is premised on the fact that it falls within the same price range and shares the same screen size (10.8) as Htab Zero. The baseline product which is HUAWEI MediaPad M5 Pro has several problems.

One of them is that it has little room for improvement, in terms of power consumption. It also has fewer opportunities for development because of its strict manufacturer’s specifications. Htab Zero emerges as a more superior product because it strives to address some of the challenges associated with the baseline product. Its system and business model are described below.

System Employed and Business Model

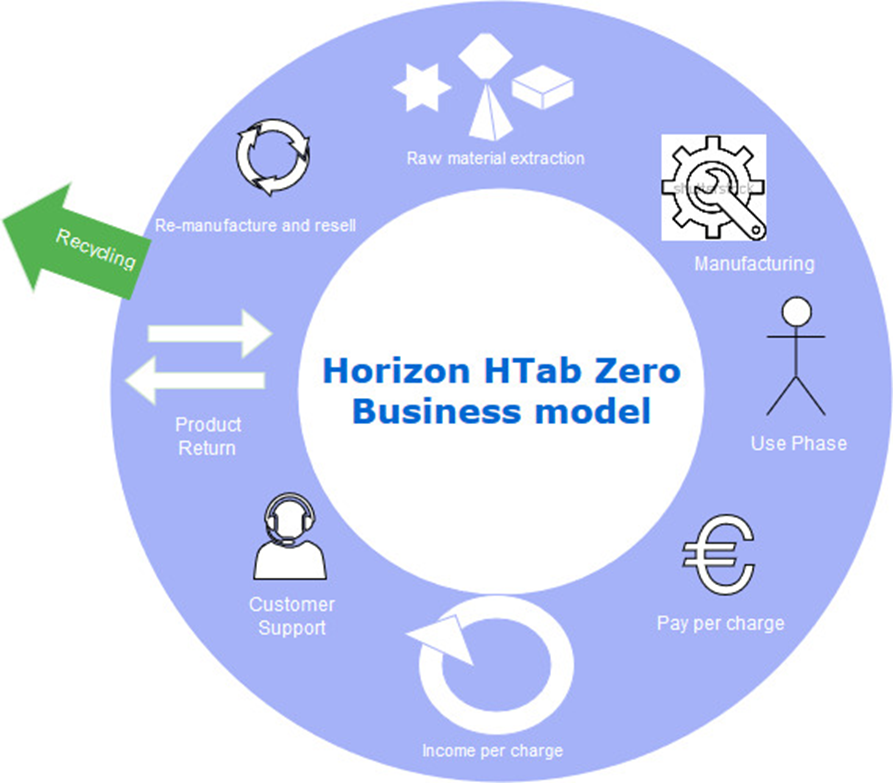

The circular system will be employed as a model for producing the new tablet. It is premised on an eight-stage framework, which includes raw material extraction, manufacturing, use phase, pay per charge, income per charge, customer support, product return and remanufacturer. These different parts of the model interact in a cyclic manner as defined in figure 1 below.

Kunz et al. (2018) say that the circular system, which underscores the development of the H-Tab Zero Business Model helps to make companies more responsible for the waste they produce. Particularly, the researchers drew attention to the fact that circular systems increase extended producer responsibilities (EPR) (Kunz et al. 2018). Wells (2016) also supports this system by saying it is an ideal business model for fostering sustainability in organisations. However, the researcher says the circular business model needs to be contextualised to an industry or organisation where it will be implemented because they may have unique dynamics for consideration (Wells, 2016).

The business model employed for the new tablet is based on the pay-per-charge framework. This framework allows customers to get a tablet upon signup. Thereafter, customers are billed every time they charge their devices. The price will be €5 per charge. To monitor tablet usage, software will be installed in the gadget and it will keep track of when the device is charged and by what percentage. It is estimated that on average, the tablets will be charged at least twice a week. At €5 per charge, we expect to make about €520 in a year.

System Enabling and Other Environmentally Superior Technologies Employed

The use of plastics to manufacture tablets has been considered a significant environmental issue because of the non-biodegradable nature of the raw material (Starik & Turcotte 2014). In our new operating model, plastic use will be limited. The limitation is hinged on the use of aluminium, which is a more environmentally friendly raw material compared to plastics. Similarly, it is easier to recycle aluminium compared to plastic.

Another improvement that will be integrated into the manufacturing process of the new tablet relates to disassembly technology. For example, standard Philips head screws will be used to repair and maintain the gadgets. The modular electronics design will also be added to the tablet as another feature. It will help to improve its functionality and reduce its environmental impact. The amount of adhesive used in the manufacture of the tablet will also be minimised. This will add to its improved environmental record because it will reduce resource demand.

Collectively, the system-enabling superior technologies highlighted above will improve the functionality of the new tablet. For example, besides making the product unique to the baseline tablet, it will improve its lifetime energy consumption. At the same time, the technologies used will simplify the disassembly process. Therefore, users will find it easy to repair the gadget faster than they would service the baseline product. Lastly, the technologies will allow the product to have a slow resource loop because materials will exist in the market for a longer period.

A Life Cycle Quantitative Assessment Demonstrating Improvement from the Baseline Study

As mentioned in this report, the baseline tablet could be improved because it has several flaws, in terms of the product development process and the business model that characterises it. The problems plaguing the baseline product are premised on three main issues – raw materials, energy and waste management. However, these problems are not unique to the gadget because several research studies have shown that waste management, limited raw materials and high-energy consumption are common problems affecting technology companies (Selva, Balakumaresan & Bharath 2016; Patil 2016; Hossain, Al-Hamadani & Rahman 2015; Needhidasan, Samuel & Chidambaram 2014).

Another problem associated with the baseline product relates to disassembly and availability of spare parts. At the same time, the production of the baseline product does not reflect the circular business model despite the existence of numerous pieces of evidence that demonstrate its benefits. For example, Kalverkamp and Raabe (2018) say the circular system helps to enhance resource conservation strategies and improve sustainable outcomes for different companies.

This finding was reported after the researchers examined the effects of the circular economic system in the automotive industry (Kalverkamp & Raabe, 2018). Similar to the electronics industry, the authors also emphasised the need for policymakers to review the designs of automobiles to improve their environmental record (Kalverkamp & Raabe, 2018).

A different study conducted by Andrews (2015) also highlighted the benefits of employing the circular economy model and demonstrated that although it is not widely employed, it offers immense benefits to different organisations. Particularly, the study showed that the circular system improves sustainability and expands employment opportunities (Andrews 2015). However, the author says that designers play an important role in making sure companies transition well from adopting the principles of the linear economy to using those of the circular economy (Andrews 2015).

The baseline product identified in this report has not made this transition because it follows a take-make-use-dispose model, which is not environmentally friendly. However, the new tablet proposed supports a radical shift of the business model to a circular one. Many more studies have supported the pivotal role that the circular system plays in improving organisational sustainability.

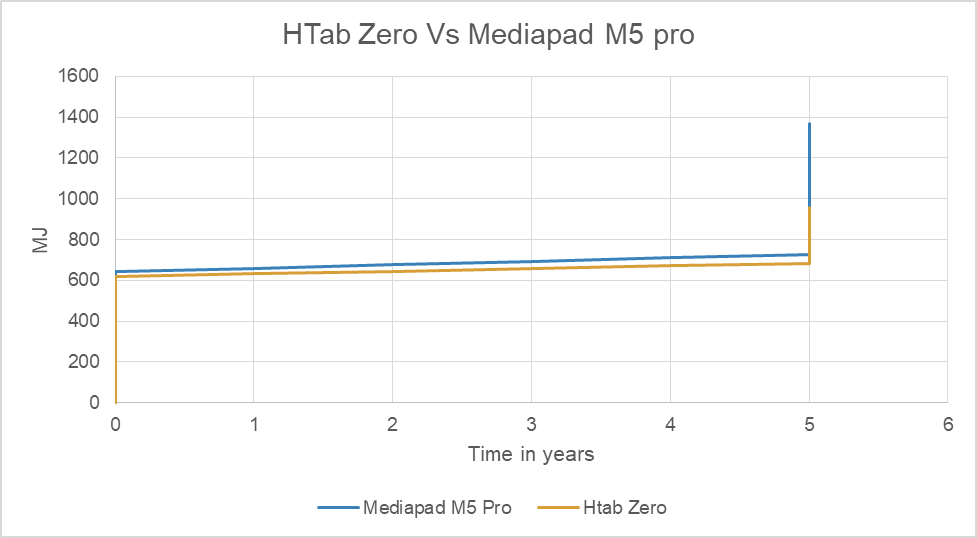

They include those authored by Esposito, Tse and Soufani (2018), Hopkinson et al. (2018). Collectively, the solutions employed to address the above-mentioned issues are integrated into the new design of the Htab Zero and are premised on the use of cloud computing technology, implementation of circular systems, substitution of raw materials and disassembly of technology. Figure 2 below shows the potential quantitative improvement of the new tab compared to the baseline product.

How the Solutions Mitigate Against the Resource, Energy and Waste Issues Identified

The solutions identified in this paper help to mitigate against waste generation as an inherent production problem because they make the company accountable for the waste generated by its products. For example, by encouraging customers to bring their old gadgets to the organisation for a replacement, the firm will be accountable for the electronic waste its products generate. At the same time, reducing the use of raw materials, which have a high environmental impact, such as plastic, help to minimise the environmental impact of the products developed.

The adoption of the circular system as a business model also mitigates against high-energy consumption and waste generation that is synonymous with electronic companies. The circular system helps to minimise waste by making sure no opportunities for energy conservation and waste minimisation are untapped. Furthermore, the system creates high levels of efficiency in the production of the tablets. The same benefits are also associated with the adoption of cloud computing services to support the functions of the tablets because technology reduces the resource demand for undertaking computation services (Li et al. 2017).

The centralised nature of cloud computing services also minimises the need for the company to spend a lot of energy in running different aspects of the product development process (Mohammed et al. 2017; Perrons 2015). However, Perrons (2015) proposes that the process of adopting cloud computing services should be flexible to allow organisational structures to complement the technology. Without such flexibility, it would be difficult to holistically realise the system-wide benefits of cloud computing.

Tackling Industry Level Issues

One of the main problems affecting technology companies is the heavy impact electronic devices have on the environment (Mavropoulos, Tsakona & Anthouli 2015; Bob et al. 2017). Recycling has been touted as one of the major solutions to tackling this issue, but this proposal has been plagued by the inability of technology companies to get their customers to return old products to them (Li, Yang & Liu 2015).

Our new business model aims to tackle this problem because it is designed to allow customers to return old tablets and have them replaced with new ones. The benefit that the customers will get by visiting our outlets will be to get new gadgets, but the company’s benefit will be to have a steady stream of raw materials for recycling. This business model allows the company to control its waste and develop a steady stream of gadgets that can be disassembled and the parts used for refurbishment. However, the most important advantage of this model is that it allows us to control waste.

Lastly, to make the new tablet user-friendly to customers, it will be designed with easy starter upgrades that the customer could purchase. The tablets will also be repairable, thereby making it easier for customers to get more value for their purchases. To ease the process of repairing the devices, we plan to launch a store that will be equipped with new and refurbished parts. The parts will also be reasonably priced.

Their affordability and availability will make it easy for the customers to upgrade their products. Relative to the fact that the circular system is the main operational model for developing the new tablet, future design operations should be based on the adoption of new and revolutionary technology such as 3D printing (Garmulewicz et al. 2018). This technology has been highlighted as a revolutionary and useful tool for manufacturing new products from locally sourced raw materials. It also has a positive record in materials recycling (Garmulewicz et al. 2018).

Reference List

Andrews, D 2015, ‘The circular economy, design thinking and education for sustainability’, The Journal of the Local Economy Policy Unit, vol. 30, no. 3, pp. 1-13.

Bob, U, Padayachee, A, Gordon, M & Moutlana, I 2017, ‘Enhancing innovation and technological capabilities in the management of e-waste: case study of South African government sector’, Science, Technology and Society, vol. 22, no. 2, pp. 332-349.

Esposito, M., Tse, T., & Soufani, K 2018, ‘Introducing a circular economy: new thinking with new managerial and policy implications’, California Management Review, vol. 60, no. 3, pp. 5-19.

Garmulewicz, A, Holweg, M, Veldhuis, H & Yang, A 2018, ‘Disruptive technology as an enabler of the circular economy: what potential does 3D printing hold’, California Management Review, vol. 60, no. 3, pp. 112-132.

Hopkinson, P, Zils, M, Hawkins, P & Roper, S 2018, ‘Managing a complex global circular economy business model: opportunities and challenges’, California Management Review, vol. 60, no. 3, pp. 71-94.

Hossain, S, Al-Hamadani, SM & Rahman, T 2015, ‘E-waste: a challenge for sustainable development’, Journal of Health and Pollution, vol. 5, no. 9, pp. 3-11.

Kalverkamp, M & Raabe, T 2018, ‘Automotive remanufacturing in the circular economy in Europe marketing system challenges’, Journal of Macromarketing, vol. 38, no. 1, pp. 112-130.

Kunz, N, Mayers, K & Van Wassenhove, LN 2018, ‘Stakeholder views on extended producer responsibility and the circular economy’, California Management Review, vol. 60, no. 3, pp. 45-70.

Li, J, Yang, J & Liu, L 2015, ‘Development potential of e-waste recycling industry in China’, Waste Management & Research, vol. 33, no. 6, pp. 533-542.

Li, R, Li, Q, Huang, N & Kang, R 2017, ‘A simplified reliability analysis method for cloud computing systems considering common-cause failures’, Journal of Risk and Reliability, vol. 231, no. 3, pp. 324-333.

Mavropoulos, A, Tsakona, M & Anthouli, A 2015, ‘Urban waste management and the mobile challenge’, Waste Management & Research, vol. 33, no. 4, pp. 381-387.

Mohammed, F, Ibrahim, O, Nilashi, M & Alzurqa, E 2017, ‘Cloud computing adoption model for e-government implementation’, Information Development, vol. 33, no. 3, pp. 303–323.

Needhidasan, S, Samuel, M & Chidambaram, R 2014, ‘Electronic waste – an emerging threat to the environment of urban India’, Journal of Environmental Health Science and Engineering, vol. 12, no. 36, pp. 1-13.

Patil, K 2016, ‘Macro perspective: e-waste environmental impacts’, International Journal of Applied Engineering Research, vol.11, no. 7, pp. 4866-4873.

Perrons, RK 2015, ‘How the energy sector could get it wrong with cloud computing’, Energy Exploration & Exploitation, vol. 33, no. 2, pp. 217-226.

Selva, PA, Balakumaresan, R & Bharath, S 2016, ‘Electronic circular board using GSM technology’, International Journal of Research In Computer Applications and Robotics, vol. 4, no. 11, pp. 6-12.

Starik, M & Turcotte, MF 2014, ‘With a little (urgent) help from our friends: management academic leadership for a sustainable future’, Organization & Environment, vol. 27, no. 1, pp. 3-9.

Wells, P 2016, ‘Economies of scale versus small is beautiful: a business model approach based on architecture, principles and components in the beer industry’, Organization & Environment, vol. 29, no. 1, pp. 36-52.