Background Information

Conventional automobiles have raised many concerns regarding their environmental impacts over recent years. According to Dharanesh et al. (2016, p. 257), there is an increased need to improve the overall efficiency of automobiles by designing regenerative braking systems (RBS). The authors further illustrate that RBS is used to convert vehicles’ mechanical energy plus the heat energy that would have been lost into electrical energy during braking.

RBS most important aspects include power generation and braking. The primary goal of an RBS design is to ensure stable braking performance and efficient energy use (Xiao, et al., 2017, p. 2). Various types of RBS exist, which are challenges to some people as they lack adequate background knowledge on the most effective systems for use in electric and hybrid automobiles. According to Perktold, Ing, and Tum (2016, p. 6), RBS offers one of the most promising technologies in electric and hybrid vehicles due to many reasons: beneficial functioning properties and senior design project constraints in regards to budget and scope.

Many current hybrid and electric automobiles use RBS to recover and reuse some energy from the braking processes. This technique contrast with conventional braking systems that convert excess kinetic energy into unwanted and wasted heat and noise through friction. RBS systems recover energy by using electric motors as generators to convert kinetic energy into electrical energy that can be used to charge batteries. Furthermore, this process improves the overall efficiency of the automobile; for example, regeneration extends the life of the braking systems by preventing wear and tear. Hence, this report illustrates the schematic of an RBS in modern hybrid/electric cars, its working principles, and the key advantages and disadvantages of an RBS and its efficiency.

Aim and Relevance of the Topic

Regenerative braking systems have gained popularity as car manufacturing companies strive to provide environmental-friendly automobiles. These systems increase vehicles’ efficiency by recovering part of their energy that is used for braking. RBS uses the moment of inertia of an actuator to lose speed instead of using friction. The increased demand for less fuel-consuming and less polluting cars (electric and hybrid automobiles) has prompted the high use of regenerative braking systems. Perktold et al. (2016, p. 7) underscore the limitation of driving mileage of electric cars as a hindrance to fully introduced RBS. Therefore, the selection of the regenerative braking system technology is a key point or area to be researched.

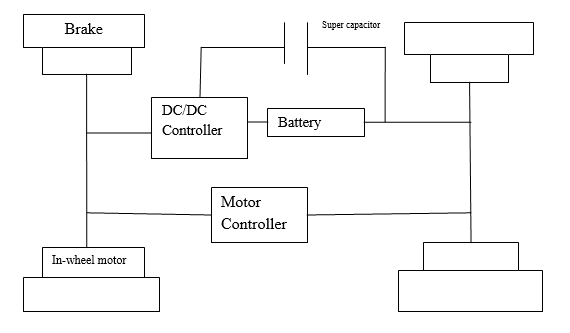

Schematic of an RBS in Modern Hybrid/ Electric Cars

Basic Element of Regenerative Braking System

A functioning regenerative braking system comprises of four elements:

Energy Storage Unit

This element performs two key functions: recovering and storing braking energy and absorbing excess engine energy when performing light load operations.

Batteries

Regenerative braking systems use the electric motor as a generator when the brake pedal is applied. The car uses its kinetic energy to generate electricity that is then used to recharge the batteries. Some of the energy is lost to resistance as it travels from the wheel to the axle and into the battery.

Regenerative Brake Controllers

These are electronic devices that can be used to control bakes remotely. Brake controller directs electricity into the batteries during the braking operation.

Primary Controller

It maintains a sufficient level of charge (reference charge) in a supercapacitor.

Working Principles of an RBS

Regenerative braking systems use the motor of a hybrid or electric vehicle as a generator to convert kinetic energy to stored energy during braking. Much of the stored energy is then used during acceleration. Regenerative braking takes the inefficiency of braking and makes the process less wasteful. RBS works under the principles of reusing energy that would otherwise have been lost in the form of heat or sound.

Dharanesh et al. (2016, p. 257) apply the example of a bicycle fitted with a dynamo to explain the basic idea of regenerative brakes. The authors illustrate that if the bicycle has a dynamo on it to power the lights, then it is harder to peddle when the small electricity generator is engaged than when it is switched off (Jin et al., 2015). The reason behind this is that some of the peddling energy is being lost and converted into electrical energy in the lights. A regenerative braking system uses the same principle in which some energy is lost or stored during braking and used during acceleration.

Automobiles driven by electric motors utilize the motor as a generator during regenerative braking. According to Dharanesh et al. (2016, p. 258), the motor operates as a generator during braking and its output energy or energy lost is supplied to an electrical load to provide the braking effect. There are different types of regenerative braking systems based on the mode of energy storage.

Electrical Regenerative Braking

Electrical regenerative braking is used in a hybrid system motor coupled to another power source. This type of regenerative braking includes an electric system that is driven by an electric motor only acting both as a generator and motor. This system comprises four main components: engine, generator/motor, batteries, and electronic control system.

Hydraulic Regenerative Brakes (HRB)

HRB systems use electrical components and hydraulics tom improve car fuel economy.

Fly Wheels

These are energy-storing devices that enhance the regenerative capacity to store energy in what is commonly known as “energy-saving reservoirs.”

Key Advantages and Disadvantages of an RBS and its Efficiency

The increased demand for less consuming and less polluting automobiles has prompted the production of electric and hybrid vehicles. The vehicles are more efficient in regard to operating costs and environmental impacts. The development of regenerative braking systems improves the energy efficiency of vehicles as they significantly enlarge the driving range and reduce emissions (Perktold, Ing and Tum, 2016, p. 21). Regenerative braking systems are the future of transportation. They have many advantages and disadvantages as discussed below:

Advantages

The regenerative braking system offers many advantages as compared to the traditional braking system. According to Perktold et al. (2016, p. 22), it has an improved fuel economy and driving range; it is characterized by properties, such as the efficiency of individual parts, duty cycle, powertrain design, and control strategy. Further, it allows more control over the braking cycle as compared to traditional braking systems.

Perktold et al. (2016, p. 22) illustrate that the regenerative braking system increases efficiency and effectiveness in stop-and-go driving. Another advantage is that they reduce the risk of wear on the mechanical brake system. Perktold et al. (2016, p. 22) point out that they have a prolonged lifespan of the vehicle battery and friction brakes as compared to traditional braking systems. Hence, over the last few years, regenerative braking systems have become popular increasing their use in electric and hybrid automobiles.

For hybrid cars, regenerative braking systems have additional advantages. According to Perktold et al. (2016, p. 23), regenerative braking systems contribute to the reduction of emissions and prevent engine wear; for example, through on/off strategy in stop-and-go driving. The use of RBS downsizes and eliminates existing components. Perktold et al. (2016, p. 22) give the example that RBS downsizes the fuel tank compensating the weight of the regenerative braking components that have been added. Using RBS in hybrid automobiles offers a comparable driving range to conventional cars common today.

Overall, RBS presents many advantages, such as better fuel economy coupled with extended driving ranges. The systems increase control over braking and reduce tear and wear on the mechanical brake systems. As a result, the lifespan of the battery and friction of brakes are prolonged. Therefore, RBS is more beneficial in cars as compared to traditional braking systems.

Disadvantages

RBS offers multiple advantages; however, it also presents some disadvantages that reduce its effectiveness. Perktold et al. (2016, p. 23) illustrate that they cannot fully replace or substitute friction brakes due to three key explanations: the wheel torque capacity of electric motors is less than the one for friction brakes, the capacity of RBS to control the braking force distribution is limited, and the response time of charging systems is restricted.

According to Perktold et al. (2016, p. 23), RBS must be designed as small as possible, but still, be efficient. In other words, vehicles have a size constraint, which demands RBS to manufactured small to fit in vehicles’ systems. Perktold et al. (2016, p. 23) also note that RBS adds extra components to automobiles that increases their overall weight. This disadvantage is common in hybrid cars as several parts have to be complemented and fuel while more weight increases fuel consumption, which cuts the actual benefits of the RBS.

The current demand for RBS is low; therefore, the company cannot manufacture RBS in large volumes resulting in high expenses for planning, manufacturing, and installation. Perktold et al. (2016, p. 23) emphasize that RBS raises safety concerns with energy storage of high energy density that is needed for the systems to function efficiently. Manufacturing companies are striving to develop RBS that do not expose passengers to dangers in case of failure.

RBS often causes unwanted noise depending on the technology used. As noted earlier, RBS reduces wear on mechanical brake systems reducing maintenance costs; however, this implies that they increase maintenance efforts for an extra component. According to Perktold et al. (2016, p. 23), RBS increases the complexity of the braking and control systems. Therefore, the efficiency of regenerative braking systems can only be maximized if these disadvantages are reduced or eliminated.

The Level of Performance of Regenerative Braking Systems

Evaluating how well regenerative braking systems work involves examining two parameters: efficiency and effectiveness. In regards to regenerative braking, these two terms are entirely different.

Efficiency

This refers to the capacity of the regenerative braking to capture energy lost during braking. Studies illustrate that no machine that is 100% efficient as any process of energy transfer will incur some loss in noise, heat, or sound. According to Patil et al. (2015), the efficiency of a regenerating braking system varies depending on automobiles, batteries, controllers, and motors. Toll (2018) illustrates that most regenerative braking systems are 60 -70 percent efficient.

According to Toll (2018), Regen loses an estimated 10-20% of energy being captured followed by another 20-20% lost by the car. This value is fairly standard in most electric cars: trucks, electric scooters, cars, and electric bicycles. Toll (2018) further explains that 70 percent does not meet that the regenerative braking will increase its capacity by 70 percent, it means that the kinetic energy lost during braking can be turned back to acceleration.

Effectiveness

Refers to the impact of regenerative braking; it is the measure of how much regenerative braking can increase range. Similar to efficiency, the effectiveness of regenerative braking varies, but this variation is caused by factors, such as driving conditions, terrain, and size of the car. Toll (2018) illustrates that driving conditions have the largest impacts. For example, regenerative braking is more effective in stop-and-go city traffic as compared to highway commuting. Vehicles driving uphill limits the chance of braking, but downhill driving regenerates more energy due to prolonged braking periods. Heavier automobiles, such as trucks have more momentum and kinetic energy when in motion as compared to small ones. Toll (2018) cites the example of Tesla cars that show regenerative braking power, such as 60kW during handbraking.

Conclusion

Regenerative braking systems have gained popularity over the recent years, especially for electric and hybrid vehicles. Traditional or conventional vehicles present many problems relating to environmental pollution. The increased demand for electric and hybrid cars have increased the popularity for regenerative braking systems as car manufacturing attempt to improve efficiency and effectiveness of automobiles. There are different types of RBS, but limited knowledge of the most effective systems has slowed their adoption.

Car manufacturing companies are exploring different types of RBS in their attempts to cut operational costs and other expenses relating to car production and environmental management. The report has focused on three key areas; the schematic of a regenerative braking system in electric cars, their working principles, and their key advantages and disadvantages. A basic RBS is made up of four elements: energy storage unit, batteries, regenerative brake controller, and primary controller.

They work under the basic principle of converting kinetic energy to stored energy that is later used during acceleration. Common types of regenerative braking systems include electrical regenerative braking, hydraulic regenerative braking, and flywheels. RBS has many advantages and disadvantages. For example, these systems have improved fuel consumption and driving range. They increase the effectiveness and efficiency in stop-and-go driving.

On the other hand, they cannot fully substitute friction brakes since their wheel torque capacity in electric motors is less as compared to one for friction brakes. They also have size limitations to fit into the care and maintain standard weight. Overall, regenerative braking systems are efficient in regard to energy consumption increasing their popularity among electric and hybrid car manufacturers.

References

Dharanesh, C et al. (2016) ‘Regenerative Braking System.’ International Journal and Magazine of Engineering, Technology, Management, and Research, 3(5), pp.257-264. Web.

Jin, L.Q et al. (2015). ‘A study of a novel regenerative braking system based on supercapacitor for an electric vehicle driven by in-wheel motors.’ Advances in Mechanical Engineering, 7(3).

Patil, S.G et al. (2015). ‘The regenerative braking principle by using the kinetic energy recovery system–a review.’ 2(2). Web.

Perktold, F., Ing, F.P.D.I.D. and Tum, M.R.M., (2016). ‘Research on a regenerative braking system for a golf cart’: pp 1-92. Web.

Toll, M. (2018). ‘Regenerative braking: How it works and is it worth it in small EVs?’ – Electrek. Electrek. Web.

Xiao, B., et al. (2017). ‘Enhanced regenerative braking strategies for electric vehicles: Dynamic performance and potential analysis.’ Energies, 10(11), pp.1-19.