Introduction

The newly acquired 37,000 mt dwt product tanker upon sailing into the sea was a subject of survey and inspection. The inspection report covered all aspects of Load Line; Structure and Stability; Live Saving Appliances; Safety and Navigation Equipment; Fire Fighting Equipments and Bilge Pumping Arrangements. This was to certify that the ship adhered to established standards and conventions for seafaring vessels. Among the conventions was the International Association of Classification Societies (IACS) covering aspects of safety and seaworthiness for seafaring vessels under the Intentional Maritime Organization (IMO). IACS was the body responsible for ensuring member countries adhered to specifications and conventions passed and ratified by member countries. The convention covered all aspects of safety and other issues of safety and other related practices. Salient features specific to the established benchmarks were identified and verified against those of the ship. These standards provided the criteria for identifying all structural and equipment status with the aim of benefiting from the ability to document every aspect of the ship in line with Panama, the country of registration’s maritime laws. This could ensure adherence to uniform standards, the ability to detect deviations from the set standards, and the ease with which it could secure charters among other benefits. Of interest was that the ship was under the flagship of Panama and was covered by LLYODS among the other classifications including BV, DNV, NKK, GL, LLYODS, and ABS. In addition to that, the company staff had to be well skilled in assessing the complexity of the ship in all aspects of the survey. In addition to these, the inspection team looked at all aspects of the structural strength of the ship particularly emphasizing the need for the vessel to withstand rough seas and remain intact, the level of water tightness of its compartments, and aspects dealing with stability. Of importance was the health of the crew while at sea. Therefore the need to have appropriately positioned bilge pumps with the capacity to pump wastes and water from the ship in addition to the mechanism that could be used, either hand-operated or machine operated and all other flexibilities were identified and compared with the standardized requirements. Communication, tracking of the sea vessel, its satellite capabilities, navigational equipment, and other satellite tracking equipment were evaluated against IMO standards envisaged in IACS and the maritime laws of Panama. The report investigated the ability of the ship’s crew to fight onboard fires and took a detailed investigation on the kind of fire fighting gears in the ship and their compliance with maritime laws of the country of registration and the International Maritime Organization requirements envisaged in IACS conventions.

Load line

In matters of the survey, a ship must adhere to standards and regulations set by IACS and the maritime laws of the country of registration and flagship covered under the International Maritime Organization (IMO). These conventions provide guidelines on loading and the stability of a ship. The level to which the draught of a ship must be loaded significantly impacts its seaworthiness and safety (International Convention On Load Lines 1). Load line conventions covered issues of watertight integrity of the ship in question, freeboard, structural strength, the height of the deck, its transverse stability. According to the article, International Convention On Load Lines (2), design and construction of the hull form, specific description of the shape of its underwater hull, the division of compartments in addition to evaluating the vessel reserve buoyancy about its full length were evaluated.

Load Line conventions were a culmination of other conventions used before LLOYD was adopted internationally with several amendments leading to the 2003 convention that entered into force in the year 2005. Several regulations were identified to be the basis for surveying the new ship. These included ANNEX 1 regulations for identifying, determining, and marking load-lines. According to these requirements, a ship reasonably complies with all stability requirements and can withstand excessive structural stresses, and complies with the international regulations and requirements on structural stability. Among the regulations are:

The hull’s strength

The inspection team certified that the draught was of adequate strength and complied with the maritime laws of the flag country and international requirements. This was by regulation one. Regulation two of the convention identified several requirements on a practical basis. The ship must be propelled mechanically to be assigned a freeboard. According to regulation 3 of the convention, the ship shall be 96 percent covered by a waterline while 85 percent covered its molded depth down from its keel on the water line considering the longest length (L) of the ship (International Convention On Load Lines 5). The water line shall comply with forwarding and perpendicular measurements from amidst the ship. The breadth shall comply with the requirements for a double hull 37,000 dwt ship measured from the shell without and with the same or different construction materials.

Molded depth

The perpendicular distance of the ship’s keel measured vertically from below the ship’s keel rabbet made hollow at some point amidst the ship which is made of composite materials. The side shell plating and the moulded lines meet at the moulded depth angularly measured. The freeboard deck consists of an extension where a parallel line must be identified over the moulded part. Therefore the ship capacity in cubic units of the ship’s moulded displacement was a combination must be characterized by these requirements to meet the standards set by the country of registration’s maritime laws (International Convention On Load Lines 6).

Freeboard depth

This is a combination of the moulded depth and the stinger plate added to the mathematical requirement of the product of T and the difference of L and S as a fractional coefficient of L, mathematically expressed as [T(L-S0]/ L. The factor T is the average thickness of the covering material above the deck’s exposure points, S is the combined length of the ship. Freeboard length will be defined by measuring the radius of the gunwale of a 4% radius of curvature.

The inspection team used the ship’s block coefficient which was the displacement of the volume of construction materials indicated by the displacement on the ship’s displacement line. The team calculated it mathematically based on the formula Cb = /L.B.d1, where the values d1 account for a 15 % difference of the total of the least moulded depth. The ship was required to comply with freeboard measurement above the load line measured perpendicularly amidst the ship vertically. According to the International Convention On Load Lines (8), the freeboard’s deck or superstructure was surveyed against the AICS requirements. The superstructure was surveyed to determine if was appropriately enclosed, had sufficient structural strength, sufficiently enclosed, was fitted with appropriate openings such as doors, and that external weather conditions could not influence or interfere with the internal environment. Flexible access to machinery was a requirement and had to be thoroughly inspected to determine openings for accessing machinery as according to the requirements of the conventions. This was in addition to the fact that the poop provided alternative access routes to machinery when all other openings were closed. The length (L) and height (H) of the superstructure were in accordance with the average value measured against the length L of the superstructure. The measurements of the superstructure were in accordance with the requirements taken vertically with the freeboard as the datum level. In addition, the condition of the freeboard with regard to its ability to prevent water from leaking into the ship was investigated and found to be compliant.

Deck line

Other issues put to thorough inspection included the load line. The requirement stipulated a 300 mm long line and 25 mm in width. The mark shall be amidst both sides of the ship. The international load line certificate shall contain all details regarding the datum line of the markings. This could be in addition to the load line mark specified to be 25 mm in breadth and 300 mm longer crossed over by a 450 mm line running horizontally at the center of the ring amidst the ship above the top of the edge line (International Convention On Load Lines 8).

The convention identified another line to be integrated with the load line. These included the summer load line bearing mark S, winter load line uniquely identified by letter R, Winter North Atlantic load line covered by letters WNA, Tropical load line uniquely identified with letter T, and the Tropical freshwater line identified by letter TF. All these load lines were uniquely identified and were clearly indicated on the ship. These load-lines met the requirement of white or yellow colors clearly marked on either side of a ship.

Structure and Stability

The ship’s stability was based on its design, buoyancy, and the effect of the ship’s center of gravity and its buoyancy. Of special importance were the Bilge keel, outriggers, antiroll tanks, paravanes, stabilizer fins, and other active stability systems. This product tanker was identified to comply with the IACS conventions classed under LLOYDS which required a ship to withstand certain aerodynamic forces. These additional stability measures included an inspection of the ship’s Bilge keel.

Bilge keel

The tanker was required to integrate two Bilge keels for hydrodynamic stability. Close inspection revealed that the ship’s Bilge keel ran across its whole length fixed near the bottom of the hull thus influencing the ship’s draught. The V-shaped bilge keel perfectly fitted into the bend of the bilge. Fitting Bilge keels were identified to be advantageous in space utilization among other loads as an additional requirement. The disadvantage identified with this structural fitting was in reduced forward motion, but the benefits were noted to be twofold.

The requirements were specific on the design and installation of the Bilge keel. It was an engineering requirement to reduce cross-flow characterized by the position of the Bilge keel along the ship’s flow line. The degree of taper of the Bilge keel in its installed position was critical considering the tanker’s heel and pier.

The tanker’s Bilge keel was constructed flat with the aim of reducing the likely occurrence of a roll motion. The ship’s antiroll tanks were inspected against IACS standards according to the outlined requirements. These tanks were identified to be integrated into the tanker whose purpose was to ensure the ship withstood the effects of its rolling motion. Upon inspection and testing, the baffles were noted to transfer water efficiently and effectively between the port side and the starboard of the product tanker conforming to the standardized requirements. An investigation into the free surface effect on the ship was tested on the vessel’s behavior in seawater to determine the level of its resistance to capsizing. Capsizing was identified to be a problem with the product tanker due to sudden changes in water flow, increased turbulence, when partially full, empty, or fully loaded. It was a requirement that the ship is fitted with smaller components with a better effect on the ship’s stability. Inspection along this line yielded similar compliance information. This could place the ship in a position to resist any hazards and other stability-related problems out in the sea. The metacentric height of the ship was determined to be IACS compliant along with its slosh dynamics. In addition to these investigations, the Paravanes of the ship were investigated. These requirements were met with regard to turbulent motions a ship at times is subjected to while at sea. Certain waves can cause a ship to roll over and sink. Therefore the construction particularly of the keel plays an important role in ensuring a ship’s stability. Satisfactory results were obtained upon inspection and testing of the ship’s stability and behavior in such conditions according to the maritime laws of Panama with due regard to the International Maritime Organization.

Paravanes

Though not a stringent requirement, paravanes were a requirement characterized by their wings.

Stabilizer fins

The ship’s stability was of main concern as it was a requirement not only to adhere to international conventions and the maritime laws of Panama but to ensure that the seafarer was safe and its load crossed through different seas safely, stabilizer fins were a necessity. An inspection revealed that the fins were built into the tanker and below the waterline. It was noted that the actual advantage of these fins was their ability to provide a high degree of stability for the tanker. In addition to that, the angle of attack could lead to minimized fuel usage. Thus stabilization was a component identified to be vital when the ship was at rest and in motion. Sometimes a ship’s motion in the sea at times may be very unsteady due to violent storms particularly when cruising in rough and stormy seas. To address these events, a ship must be designed and appropriately equipped with such stabilizing mechanisms to help overcome or counteract such situations. The stabilizers were put to further tests and verification. In essence, the construction materials were analyzed to verify compliance with international maritime engineering standards. The team conducted scrutiny on these materials and the documented materials. The materials were satisfactory of the required standards and provided the kind of structural strength for stabilizer construction in terms of their tensile strength, hardness, and corrosion resistance. The inspection team identified specific calculations against IACS requirements under IMO conventions requirements in relation to the stability of the ship. As a standard, the ship was

Other areas of inspection were in relation to intact stability where the stability height was assessed, circular curves under the GZ, and trim level. Another benchmark included the ship’s serviceability in the event of damage, lubricant provisions, and the sea chest. It was certified that the tanker met the requirements pertaining to the sea chest. All other requirements including the provision for coolants, water, and other functional fluids were inspected and found to be in harmony with the requirements.

Other stability investigations centered on light and full displacement stabilities.

Of importance was damage stability where an inspection was conducted to determine how the ship could behave in relation to an assessment of the ship’s stability when fully damaged or in the aforesaid condition.

Active stability system

A requirement by IMO convention integrated into the AICS conventions was vital in determining the active maneuverability of the ship in relation to its use of onboard equipments to provide relative stability for the ship by the use of system pumps to direct a fluid against opposing forces and a ship’s motion to create stability when threatened with a dangerous condition.

Live Saving Appliances

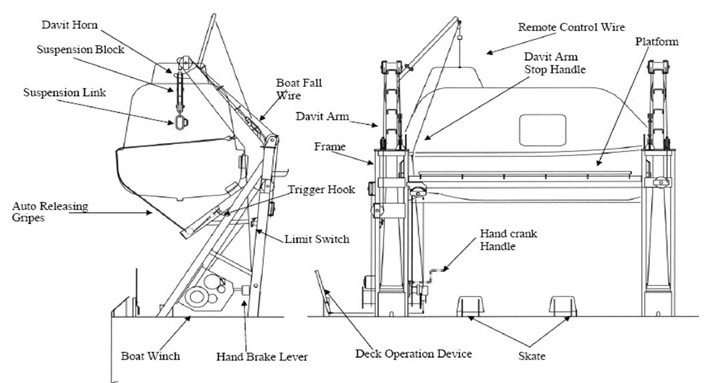

In line with IMO conventions integrated into AICS, live-saving equipment formed an important part of the inspection survey. This was a standard to ensure seafarers were safe under normal seafaring ventures in addition to taking contingency measures in the event of a disaster. Appliances inspected included lifeboats to ensure free fall requirements were integrated into the design of the boat. In addition, the inspection was based on the availability of lifeboat equipment. Other items of interest were LSA gas inflation systems, manual pumps for lifeboats, sea anchors, foam buoyancy materials, lifejackets, emergency lockers, liferafts radar reflectors, immersion suits, floating appliances, and embarkation ladders. The requirements included identifying specific descriptions of lifeboats and their requirements while evaluating compliance with them. The tanker had all types of lifeboats including fully enclosed ones, partially enclosed ones, rescue boats, and speedy rescue boats. The requirements were fully met according to the International Maritime Organizations and the IACS conventions. The ship was further identified to comply with the international code of signals, and the sound reception arrangements were in proper working conditions. In the event of losing course, the ship was installed with an automatic tracking system that could help locate it while at sea, and Gyro compass repeater was in good working conditions.

Other requirements on life-saving appliances included an exhaustive evaluation and identification of those appliances in accordance with regulation eleven indicating where lifeboats were stored in the ship, lighting of access points, in routes, and exits. The launching points were required to be clearly illustrated where they should be kept perpetually accessible in the case of any emergency, line throwing appliances must be made available at any point in time. Alarms must be displayed clearly for any seafarer to use in the event of an emergency; the equipment was thoroughly tested for compliance with the IMO conventions and the IACS requirements as outlined by LLYODS. In addition to that performance standards for the crafts were verified against the requirements of 37,000 dwt the ship. Other tests included onboard fire drills.

The ship was inspected for emergency exit outlets and found to comply with the IMO conventions and other maritime laws as was a requirement by the country whose flagship the ship was registered with.

Safety and Navigation Equipment

Of fundamental importance is the safety not only of the seafarers but the safety of the sea-faring vessel. A thorough investigation of navigational equipment revealed that the standard magnetic compasses were in good working order and the ship was equipped with two of them in addition to three spare magnetic compasses and three radar transponders. This could provide effective communication and navigational abilities for the double hull 37,000 dwt tanker at sea.

Other navigational equipment identified on board and consistent with the standard requirements and the countries maritime laws included Gyro compasses, the track control arrangements, pelorus device for accommodating compasses, data communication or transmitting device referred to as transmitting heading device (THD), a pair of radars with different levels of frequencies, the AIS system which was purposely installed to provide automatic tracking capabilities, a system which recorded sea voyages commonly termed as automatic voyage recorder, velocity, and mileage recording device for measuring distances in water, and a device for measuring echoes when at sea. The ability of the ship to automatically plot its voyages and track the sea-faring routes was enhanced by the voyage data recorder (VDR) machine. A board radar reflector was inspected, tested, and found to be compliant. The rate at which the turn indicator blinked was also put to the test and found to comply with the international standards and maritime laws of Panama. The number of nautical maps and ease with which they could be read was also found to adhere to the international requirements. In the context of the global satellite system, the ship was inspected for compliance and found to adhere to the standards. It was in a sound state of receiving and sending signals.

Fire Fighting Equipments

On-board abilities to fight the fire within a transport vessel are vital. This is about the fact that inability of getting help off-board in the event of a fire. In addition to the fire fighting equipment on board, the seafarers should be trained on the use of this equipment in a restricted area. It was a requirement according to the IMO conventions and other maritime laws to have the crew continuously drilled on fire fighting techniques and use of the relevant equipment and personnel well versed in firefighting should thoroughly inspect such equipment to ascertain their compatibility (Focus On IMO 4).

Among the equipment inspected included a whole range of fire fighting gear including foam extinguishers, fire helmets, wildlands, fire fighting nozzles, hazard materials, and radios for effective communication between the crew and external contacts. Adequate water supply was identified to be a requirement met by the new ship. Water is an important component in fighting fires on board and can help quench a variety of classes of fires. In addition to that, the ship was equipped with cell phones which could provide effective communication between the crew and for seeking external assistance in fighting a fire. Focus On IMO (4) notes that, on the further inspection with due regard to the IMO conventions as inscribed in IACS standards, gloves were identified to be part of the fire fighting gear, an important requirement. In addition to that, the fire fighting equipment was checked against thread savers, fire horses and the type of horses closely scrutinized, and fire bags. Foam extinguishers were appropriately installed to provide ease of access to help put off fires on flammable substances.

Fires can be classified according to the severity and the combustible materials they consume. All these fires must be within the capability of the crew to fight and put them off with appropriate equipment. In installing this equipment, other factors must be considered. These include identifying the available free space in the ship, the number of decks, and the ability and flexibility with which the crew could run up and down the stairs in fighting the fire. The operating space may be very limited and the crew may be crammed into a small space that may hinder the effective movement of the firefighter.

Bilge Pumping Arrangements

IACS’s conventions place it as a pre-requirement that a seafaring vessel shall make available such equipment at all times and the equipment should be displayed in such a position of ease of access. This equipment should be made available at all times of the ship’s lifetime. Of special interest according to the convention is during emergencies (mca 1).

An inspection report of the new ship detailed how pipes were sealed, provision of space on the bulkheads was done, chest valves and where their relative position in the ship, operable possibilities on remote valves, drainage of the bulkheads, suction pipes, and the number of bilge pipes. The report also verified the availability and usability of bulge mud boxes and strum boxes, sounding pipes which were required to be efficiently integrated into the structure of the ship, bilge holding tanks were also required to hold water and oily wastes before being pumped out of the ship. Operational use was tested against the efficiency of the bilge pumps. Bilge pumps make moving of water and other waste material out of the ship easy and convenient. Mca’s (2) report identifies other sources of leakages to be from seawater when a ship cruises in rough seas. These benchmarks were covered under regulation 49 of the IACS convention enshrined in the International Maritime Organization (IMO). Flammable pipes were thoroughly checked and their spacing was determined against the provision of sufficient space and other requirements. Water in a navigating vessel gets foul and at times very unhealthy; to get the water out of the ship bilge pumps must work well to ensure quick pumping. If the water is left unchecked it may lead the ship to sink or may threaten the stability of a ship.

An inspection report revealed that the pumps were appropriately positioned or installed and the capability to use hands in operating the pump was appropriate. In addition, the mechanisms for operating the pump were identified to be efficient and up to date (mca 2).

The ship was investigated on matters concerning the environmental arrangements in disposing of bilge contents. The inspection team went through the disposal process and approved the disposal process. This was as a result that the team identified the manner in which the acidic contents of the bilge pump were stored thus preventing the water from spilling over to the sea. In addition to that, a further inspection was conducted to determine the corrosive resistant of the materials of the bilge pump. It was noted that it was made of corrosion-resistant materials and contingency measures were in place to ensure that the pump always remained operational and that the pump could not easily block (mca 3). Measures were put in place to ensure that in the event of blocking, the immediate response could be realized and action taken.

Conclusion and Recommendations

The inspection report pointed to an efficient sea-going vessel covered and compliant with maritime laws of Panama, the International Maritime Organization envisaged in the IACS conventions according to LLYODS. All aspects of inspection include load line requirements, structure and stability, live-saving appliances, safety, and navigational equipment, fire fighting equipment, and Bilge pumping arrangements. This equipment was inspected and tested against the benchmarks provided in the inspection manual. In addition to that, the vessel was identified to be made of structurally appropriate materials for seafaring vessels.

The inspection team recommended further inspection to be done where other laws of other countries not signatories to the charters are incorporated as it was realized that the ship may dock in some of the ports of those countries. The team recommended the crew carry certificates of verification and inspection on board to allow them to dock at any port since the certificates certified a comprehensive inspection and IMO compliance.

Works Cited

International Convention On Load Lines:The contracting Governments. 1966, Web.

Focus On IMO. International Maritime Organization.January 2000. Web.

mca: Bilge Pumping Arrangements. Maritime and Coast guide agency. 2007. Web.