It is axiomatic that every construction needs a lot of planning in order to come up with a good structure or building. It is recognized that care and attention to specification of workmanship and material are required for good structures.

The contractors need to take into consideration such important aspects like the period of the contract cost and resources. To start with, the contractor has to consider the type of construction and this ranges from roads, offices, stores, warehouses, garages and workshops (factories). There is a wide range of proprietary material on the market for building and construction. They should also take care of structural design which should be done according to the accepted standards i.e. in Britain they should use the British standards and codes of practice and compliance to those standards is very much desirable. However, these should provide only skeletons to which designment and construction should fill in necessary details.

Contractors who appear from ensuring that the design is properly made should also consider the availability of materials before they can start suppliers of materials which we have seen to be vital should also be given a notice of the above so that they can be ready for the site. The client should also be notified of any sub-contractors.

It is also very important that enough time should be given the contractor before he starts the projects because he needs proper planning of:

- Equipments and methods.

- Ordering of materials

- Preparation of a balanced program.

The time necessary should vary depending on the type of the project, nature of the project and also site of the project. This is in relation to how materials will affect the whole course of action because this is an essential preliminary to the job.

The construction planner should be very involved with the planning of his own site and should be totally in charge.

As we have discussed earlier, the a good project depends on the tile and human resources made available but even broad outline planning can advance, and thus provide opportunities for their avoidance or solution. Construction planning involves the following three elements.

- Management

- Planning

- Estimating

Planning

Construction planning we have two types of planning one that is done before the construction and it is called pre-tender planning this is done when preparing a tender and the estimates are done by an estimator who looks into the methods and the timing of operations and to enable him to consider these contract as a whole rather than as a series of isolated events. Pre Tender planning is done in order to;

- Manage company past experiences and knowledge of various departments.

- Assist in estimation of resources and tasks.

- Eliminate future controversy in construction

- Create realistic tenders.

- Improve the ratio of tender awards-

The other type of planning is project planning which is also known as preliminary planning or contract planning and it is followed by another short term planning called site planning. It is carried out by a central planning department or by a construction manager under a contracts manager. It is vital that the construction manager or general supervisor should be assisted when necessary or at least consulted in such a case.

In general planning of a building construction project is done before starting the real construction work on the site. This will ensure that materials will flow and lack of materials will not affect the site of construction. Perhaps most contractors do not realize that apart from materials, which are artificial resources they also need natural resources (people). Once all the resources have been pulled together, then the real construction-planning process take place.

Construction planning

The term construction planning means the ways or methods of how and which the construction is done with exactness, that it should have if it gives the impression has a sense of direction and destinations. It represents co-ordination, co-operation, co-operation, and contracts with the inevitable or un avoided mistakes that will come by when people act independently in their own interests, with no overall framework into which they are constructed to fit.

Construction planning is concerned with completing a contract in the shortest

- Time possible

- Compatible with economy (finances)

- Quality work done.

In order to achieve all this enough consideration should be given to the plan of action so that the contractor gives the details to the client. This detail includes:

- Starting date

- Completion date

- Handover date.

Proper construction planning is done by using C.P.M this has several other terms used to refer to It (C.P.A- CRITICAL PATH ANALYSIS) or (PERT) analysis. In any construction, the construction must run smoothly as we have seen and the aide of (PERT) analysis does this. This ensures that the affection planning is a live by operation and continuous in nature. (PERT) program (Evaluation and review technique) helps the contractor to know what to do at what time. It also assists in register monitoring of the process. In the process, the programming phase leads to the control phase with regular monitoring of the process, which in turn leads to final stage and with regular updating of the program and re-scheduling tasks. It leads proper action to be taken when there is a problem

Monitoring is done at any time called “NOW” when activities are reported to be having completed or a certain percentage should have been done and starting days or durations should be changed to update the procedure and give a time image of the project. PERT analysis formatting is now on computers when corrections can use it more effectively.

Research and costs

Since we are now living in a fast moving economic world, cost and resources should be managed effectively in every sector, thus including the construction in such a way that he/she makes initial time estimates for individual activities on the assumption that sufficient resource will be available at an economic level.

Hence, the contractor should ensure that he has the following network.

- Nature of the project

- Logic involved or method

- Time

- Resource available or desirable.

- Costs

In this context resources include

- Manpower

- Skills.

- Materials

- Machines

- Money

- Or other items likely to have limited supply.

C.P.M and critical PATTA methods

This method is highly recommended in the building and construction management and has been used since 1950s the PERT is also known as CRITICAL PATH METHOD. This method is recommended for planning control of construction of buildings in most convenient USA, Britain etc these two methods are same except the theory of application. They are used in planning, scheduling and control of construction work. They are used to overlay activities as they are done and how they should be done. They are most useful in large research on events.

PERT-D Is used to cope with uncertainty of events and here statistical methods are used and then three times estimates are given for each activity.

- Optismistic

- Most inventory

- Pessimistic

After this, a probability test is done to obtain the expected time of compulsion.

C.P.M-is used to examine the work content of any construction work of mostly large complex projects.The basis of this is to prepare a network in which each activity to be done is represented in diagrammatic form. The following shows the sequence of activities and major stages of correlated actions in C.P.M:

- Stage 1-Listing activities, noting constrains, and drawing the network.

- Stage 2-Adding time estimates for activities and, calculating floats or critical paths

- Stage 3-Agreeing networks and targets datas, and modifying networking if necessary.

- Stage 4-Monitoring progress for feedback of success or failure and remedial action if necessary

C.P.M has the following advantages

It is a flexible technique

It can be applied to a complete project or a section of a project

Details of each stage might be varied as necessary

It enables alternative courses of actions to be examined both initially or when the project is underway

Trouble spots in projects can be identified

Can be used in any project large or small

C.P.M- This is most suitable for construction projects with the time each activity is supposed to be completed is known. On the other hand, P.E.R.T. is commonly used on computers adaptations and developments. In both the methods, the activities that precede and follows each operation must be decided clearly and then recorded down. They are then done on a graphical presentation of planned program by arrows and diagrams of a grain called the arrow diagram.

In this type of techniques (P.E.R.T. C.P.M.), the main target of construction is to know the proposed time that the profit is too big to the targeted date of completion of the profit. This should be done gradually and slowly knowing the important strategy of the construction that’s why it is used in large and complex projects. For example when building a house one has to know when he has to dig the foundation, construction of floors, walls etc. Then the duration in days is indicated on the diagram to know the statistics, date and proposed completion dates to customers.

Then it should show the earliest time the event is scheduled to start.

This project is laid down the same small operations listed in the order of performance.

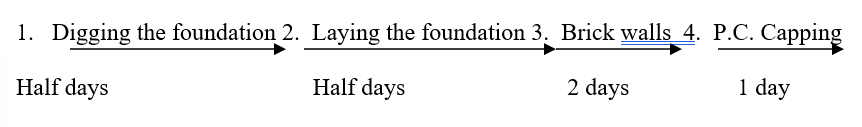

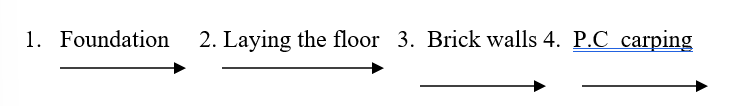

For example digging the foundation laying the floor, brick walls and precuts camping.

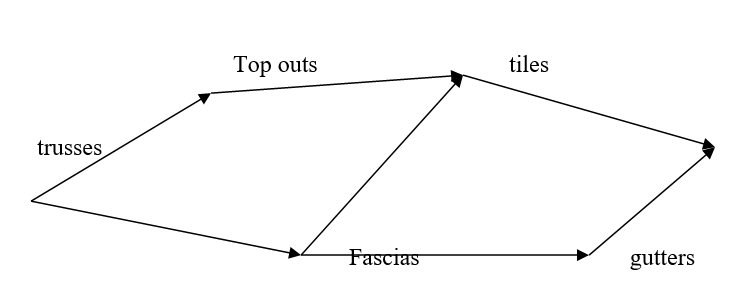

They are then shown on the precise days on which these activities can be done each an arrow shows activity. The start and finish of each event is represented by a mode or circle and has an identifying number. After this, time estimations are given to each event.i.e. half a day. The durations are then added to show the earliest starting point to the earliest completion point of each event. We can also have a parallel activities analyzing the following.

Duration Key

= earliest time of completion

= Latest time

Some activities cannot be done before the other activities, other activities can be done alongside other activities and the aim is to get the maximum time that can be taken in an emergency without delaying the overall completion time.

Good construction planning has serious implication on all aspects on the constructor of any client. These are on both labor costs and overall costs of projector. It won in town affect the completion of the project. Good planning car eliminate idle and non production time and also shortage of building material, transportation of building materials etc. For planning to be effective, it should be continued in nature. Its success depends entirely on the attitude of the planner and the methods that he or she employs to come up with a successful structure.

Time Constraints

If there is a consistent pattern of activities taking longer than planned, the projection of time to completion must consider this actual performance data. The time performance ratio is the best indicator of how well the actual durations of activities match the planned durations of activities. When appropriate, the planned duration of activities yet to be completed should be modified by the historic actual performance.

This involves modifying the durations of each activity where this is appropriate to reflect a more valid schedule. The alternative in terms of time control is to reevaluate the resource and rate of application required to maintain the original schedule. Whichever choice is made, project management and field supervisor together must make the decision and must be committed to encouraging the appropriate levels of production for the completion of the work. In the meantime, the actual schedule must be projected to completion and this should be done at regular intervals. Construction

Materials Management

Materials management is an important element in determining the success of the completion of the project. It represents a major expense in Construction, so minimizing procurement or purchase costs presents important opportunities for reducing costs. Poor materials management can also result in large and avoidable costs during Construction. First if materials are purchased early. Capital may be tied up and interest charges incurred on the excess stock of materials. Even worse, materials may deteriorate during storage or be stolen unless special care is taking. Secondly, delays and extra expenses may be incurred if materials required for particular activities are not available. Accordingly, insuring a timely flow of material is an important concern of project managers. (Manuele, F. 2005)

Material management is not just a concern during the monitoring stage in which Construction is taking place. According to Stukhart and Bell (1987), decisions about material procurement may also be required during the initial planning and scheduling stages. The availability of material may greatly influence the schedule projects with a fast track or very tight time schedule that is sufficient time for obtaining the necessary materials, must be allowed. In some case, suppliers that are more expensive maybe employed to save time. (Manuele, F. 2005)

Financial and Budget Constraints

Most projects today are financed with borrowed money. The loans bear interest, which continues to accrue until the principal is repaid from the proceeds of the sale of whatever the facility produces. Plants are normally built to produce on investment, but the investment itself is money. First, the financial institutions must be convinced that the new project is economical. The financial institutions must know that the loan will be discharged and that there is adequate security until it is discharged. Sometimes these institutions must be assured that the investment of their money is handled in a cost efficient manner.

More often than not, these financial institutions require adequate documentation before releasing funds to pay a major invoice. Some bankers even may want to be consulted before a major money commitment is made. Others, more sophisticated in their lending analysis, may want only to review the reports and verify their validity. These unavoidable delays can result and lead in lost time and money. The point that needs to be highlight here is that, whenever “S” curve is developed, this factor of financial and budget need to be taken into consideration, as it will also affect the performance of the contractor when it comes to the project completion. (Manuele, F. 2005)

Conclusion

In conclusion, C.P.M has been developed to assist in planning, organizing and controlling work where it has been successfully applied in those management functions. It does not replace or reduce the need for good management but if properly used in right place it can assist management in their roles.

References

Bluff, L. 2003. Regulating Safe Design and planning of Construction Works: A Review of Strategies for Regulating OHS in the Design and planning of Buildings, Structures and Other Construction Projects, Working Paper 19. Canberra: National Research Centre for Occupational Health and Safety Regulation, Australian National University.

Bobick, T., R. Stanevich, T. Pizatella, P. Keane and D. Smith. 1994. Preventing Falls Through Skylights and Roof Openings. Professional Safety. 39: 33-37.

Briscoe, G., A. Dainty, S. Millett and R. Neale. 2004. Client-Led Strategies For Construction Supply Chain Improvement. Construction Management and Economics. 22: 193-201.

Gun, R. and C. Ryan. 1994. A Case-Control Study of Possible Risk Factors in the Causation of Occupational Injury. Safety Science. 18: 1-13.

Hakkinen, K. 1995. A Learning-by-Doing Strategy to Improve Top Management Involvement in Safety. Safety Science 20 (2/3): 299-304.

Manuele, F. 2005. Safety Management: Risk Assessment and Hierarchies of Control. Professional Safety. 50 (5): 33-39.

Marais, K., J. Saleh and N. Leveson. 2006. Archetypes for Organizational Safety. Safety Science. Article in Press.

Mearns, K., R. Flin, M. Fleming and R. Gordon. 1997. Human and Organizational Factors in Offshore Safety Report OTH 543, Offshore Safety Division. Subdury: HSE Books.