Introduction

The purpose of this project quality management plan for the construction of the NorthConnex tunnel is to ensure that project quality is maintained and achieved as per the stated quality plan (Datta 1). Each of the project execution and implementation phases guidelines, which include project quality policies, roles and responsibilities, and procedures for ensuring that quality is achieved throughout the project lifecycle. Datta notes that the quality management plan is a document which provides detailed description of how quality is planned, managed, the quality assurance activities, quality control activities, and acceptable quality project implementation standards.

Quality management approach

According to Bassioni, Price and Hassan, the project manager ensures product and process quality are implemented in the construction of bicycle access points with a detour placed appropriately constructed in-between the two westbound lanes and other project sections (2). Construction activities that need to conform to the quality standards include modifications to existing tolling gantries, potholing for service investigations, connecting communication and power by trenching work, modification of traffic, and removal and installation of new barriers.

The project metrics include resources, schedule, costs, process performance material wastes, and customer satisfaction. All members of the project team will contribute towards implementing the project quality (Bassioni, Price and Hassan 6). Besides, the project manager is responsible for reviewing the costs of project improvement and updating the project team and quality manager on the quality improvements. Typically, according to Datta, the quality management plan components include quality requirements/standards, quality assurance, and quality control (11).

Quality Requirements/Standards

The project and quality teams determine the quality of products that results from the construction work. Documented quality standards for both the construction company and the client will provide the necessary guidelines for all construction work. Specific quality standards for each component that is used in the construction work should be consistent with current documentation (Kelly, Male and Graham 3). Prior rests are conducted to determine product quality before they are used at predetermined intervals.

Process Quality

The assurance of process quality is based on construction company process standards. The quality team works with other team members to establish quality standards that are acceptable and worthy incorporating into the organizational process documents.

Quality Assurance

According to Bassioni, Price and Hassan, each product that is manufactured and used in the construction work is evaluated through an iterative process throughout the project lifecycle (21). It has been noted that a day to day quality management report is generated with the process audits conducted on a weekly basis. To ensure compliance with the construction Company and client quality policies and standards, the quality manager and the project manager conduct regular quality reviews to determine any discrepancies.

Quality Control

Product performance, acceptable standards, and project specific quality standards are the primary areas to focus on. A sample of each component that is used in the construction work must be supplied and tested in accordance with the specified quality standards.

The project and quality managers will be responsible for conducting quality reviews and the outputs of the quality reviews reported to the entire project team, project stakeholders, and project sponsors.

Each process will be subjected to a continuous evaluation to ensure that the desired project quality is achieved and to make quality improvements where necessary based on the results of the quality audit document.

Communications management plan

Purpose of the communication plan

Gido and Clements argue that the overall purpose of the communication management plan was to promote the successful execution of the project (7). The execution plan has a scope that spans the Northern and southern interchange; the Wilson Roas support tunnel facility, construction compounds, and the Trelawney area. The project structure inputs include the management strategy, stakeholder register, communication technology and tools, and communication requirements analysis. The expected output is a complete communications management plan and documentation.

The target audience includes the project manager, stakeholders, senior leaders, and the project team (Griffith, Stephenson and Watson 11). For the communication plan to be successful, the following components were identified and integrated into the project.

Project Team Directory

Communication constraints

Communication among the project manager, stakeholders, suppliers of raw materials, functional managers, the managing director, and project teams will be communicated to though emails and status reports. However, the project manager will be required to report directly to the government authorities on the project status. Communication will occur within the project approved communication tools and budget, resources, and schedule. Standardized templates and formats must be used for all formal communication and any information must be requested for and approved by the project manager.

Stakeholder Communication Requirements

Turner notes that the method and frequency of communication of the project manager with the stakeholders will be determined based on their feedback on the preferred method to use (14). Stakeholders will also provide their preferred communication channels and the project manager must determine the resources necessary to make the communication secure and successful.

Roles

Communication Methods and Technologies

The stakeholders will use emails and SharePoint platform as a communication policy. Schedules will be communicated using PERT Charts and the company’s website.

Communications Matrix

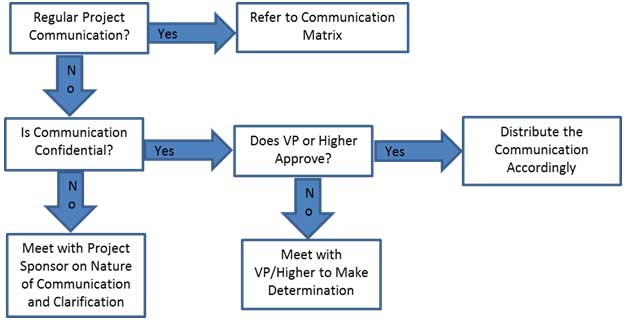

Project communication chart

The above diagram shows the communication paradigms within the project implementation cycle that is followed by the project team and occasional clarification can be done by the project manager.

References

Bassioni, Hesham Ahmed, Andrew DF Price, and Tarek M. Hassan. “Performance measurement in construction.” Journal of management in engineering 20.2 (2004): 42-50. Print.

Datta, Nirmal K. “Quality, environmental, and health and safety management systems for construction engineering.” Journal of Construction Engineering and Management (2003). Print.

Gido, Jack, and James Clements. Successful project management. Cengage Learning, 2014. Print.

Griffith, A., Stephenson, P., & Watson, P. (2014). Management systems for construction. Routledge. Print.

Kelly, John, Steven Male, and Drummond Graham. Value management of construction projects. John Wiley & Sons, 2014.

Turner, J. Rodney, ed. Gower handbook of project management. Gower Publishing, Ltd., 2014. Print.